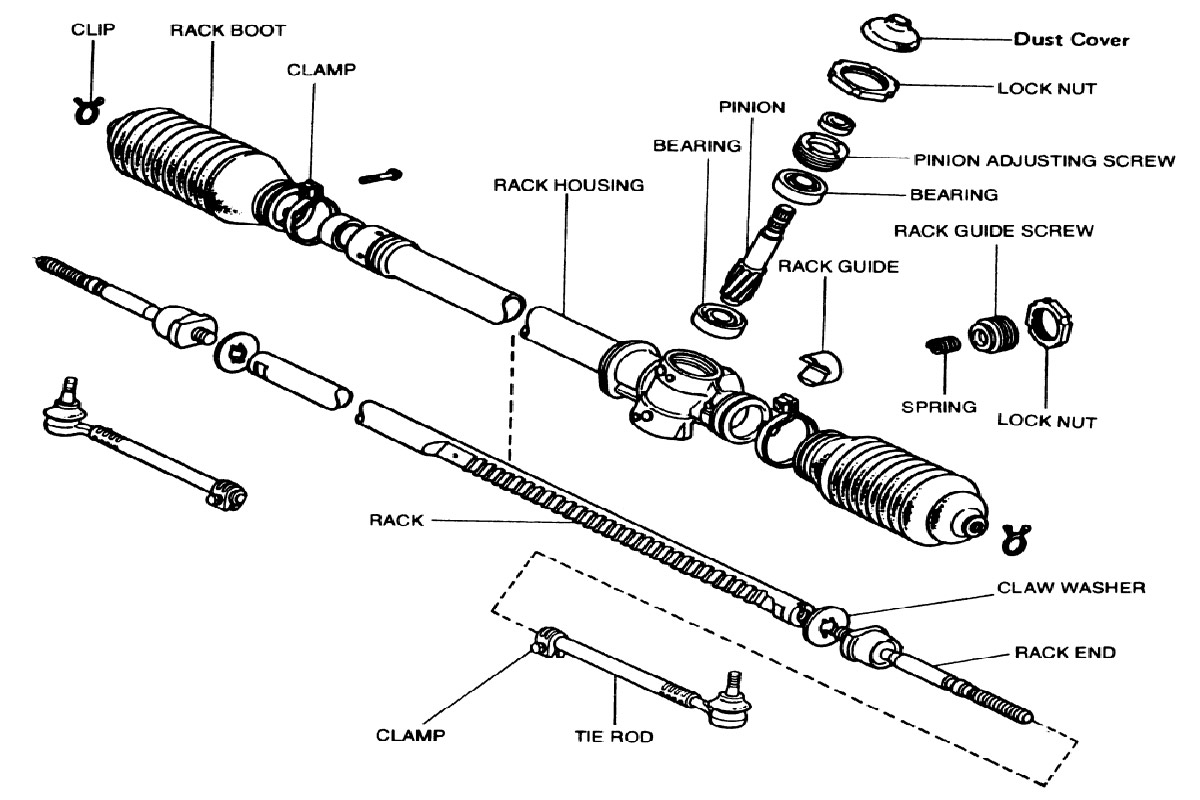

Repair Guides Steering Manual Steering/rack And Pinion

Basically, a rack and pinion are two gears which make up a gear set. These gears are positioned within a metal tube. On each side of the tube, you can see the rack coming out. There is also a component called a tie rod which ties off the ends of the rack and connects the steering arm and spindle together. The function of the tie rod is to relay.

Suspensions 101 Diagnosing the Two Basic Types of Front Suspensions RacingJunk News

Install the new rack and pinion assembly and loosely install the rack mount bolts. 9. Reinstall the fluid lines, replacing any O-rings with those supplied with the new rack. Reconnect the steering column to the input shaft. Torque the rack mount bolts. 10.

[DIAGRAM] E46 Steering Rack Diagram

Rack and pinion steering is a type of steering mechanism used in automobiles. It is the most common type of steering used in cars and small-sized trucks . The rack and pinion Steering system is based on the conversion of the rotating motion of the steering wheel into a linear motion onto the wheels and consists of two gears namely, rack and pinion which assist in turning the vehicle relative.

rack and pinion schematic diagram

Rack and pinion drives are used in machine tools, pick-and-place mechanisms, and so forth to provide linear motion of slides, gantries, etc. Sometimes a lead- or ball-screw is preferred, especially for shorter motions, but racks and pinions provide an economical way of achieving long runs. One drawback is accuracy, as the pinion and rack need a.

Need Help Putting My Rack and Pinion Back Together

The rack and pinion steering system is commonly used in modern vehicles due to its simplicity and effectiveness. It allows for precise steering control, making it easier for the driver to maneuver the vehicle. Additionally, the compact design of the rack and pinion system makes it ideal for use in tight spaces.

Repair Guides Steering Power Rack And Pinion Steering Gear

Rack and pinion. A rack and pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack ). Together, they convert between rotational motion and linear motion. Rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate.

Mavericks & Comets Articles Rack & Pinion

Rack and pinion systems are a common component in railways. A rack and pinion steering system consists of a pinion (a circular gear) with a rack (a linear gear). The system works by converting a.

Rack and Pinion Rebuild Diagram Literally, lay 21 down against the rack so that it doubles

rack and pinion, mechanical device consisting of a bar of rectangular cross section (the rack), having teeth on one side that mesh with teeth on a small gear (the pinion).The pinion may have straight teeth, as in the figure, or helical (twisted) teeth that mesh with teeth on the rack that are inclined to the pinion-shaft axis.. If the pinion rotates about a fixed axis, the rack will translate.

Rack And Pinion Parts Diagram

Hard to steer? Don't pay a mechanic! Step-by-step instructions to diagnose, service and troubleshoot a rack and pinion on automobiles. This video covers test.

Steering Systems 101 RackandPinion vs. RecirculatingBall Hot Rod Network

The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. The main components include the rack, pinion gear, bearings, and housing. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth.

Rack And Pinion Rebuild Diagram General Wiring Diagram

then for each complete revolution, 20 pinion teeth will move past this point on the diagram . As the rack and pinion are meshed, 20 rack teeth must also move past the point . If the rack has 5 teeth per centimetre then for each rotation of the pinion 20/5 = 4 cm of rack will move past the point x. If the pinion rotates at say 10rpm, the rack

What Is Rack And Pinion Steering Mechanism? How Rack And Pinion Steering System Works? Hindi

Steering 2 - Rack and Pinion hydrolics. Using a ruler, paper, pencil and your best drawing skills take some time to draw and label the components found in the hydrolic rack and pinion system. Easy: Using the attached diagram label each part of the system. Medium : Draw out the system diagram in 2D as above and then label it.

64 FSC racknpinion

Advantages of rack and pinion steering System. Advantages of rack and pinion type steering gear: 1) Rack & pinion steering gearbox is simple in construction. 2) Economical & easy to manufacture. 3) It is easy to operate with accuracy. 4) Contact between steering rack & pinion is free from play. 5) Internal damping is maintained.

How to Diagnose and Repair Rack and Pinion Bushings RacingJunk News

A rack-and-pinion steering system is prevalent in modern vehicles, enclosed in a metal tube with the rack's ends protruding from it. Connected to the steering wheel, the pinion gear rotates, causing the rack to move. Tie rods at each end of the rack link to the steering arm on the spindle, allowing for responsive and precise control over the.

I am replacing the rack and pinion in a 1990 Ford Tempo. what is the o ring config where the 2

Lucidchart's Flow Diagram Software Is Quick & Easy To Use. Free 7-Day Trial. Our Diagram Creator Makes It Easy To Share and Edit Your Diagrams—With Anyone, Anytime.

What is Rack and Pinion Steering? What to Know Explore the Future of Engineering 3D Modeling

The rack-and-pinion gearset does two things: It converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels. It provides a gear reduction, making it easier to turn the wheels. On most cars, it takes three to four complete revolutions of the steering wheel to make the wheels turn from lock to lock (from.